Why Are High-Frequency PCBs Essential for High-Speed Communication Devices?

In today’s fast-paced digital world, high-speed communication devices—such as 5G networks, satellite systems, radar, and advanced wireless technologies—rely on efficient signal transmission with minimal loss. A critical component enabling this performance is the high-frequency printed circuit board (PCB). These specialized PCBs are designed to handle high-frequency signals (typically above 1 GHz) while maintaining signal integrity, reducing interference, and ensuring reliability.

This article form DSX Electronics explores the importance of high-frequency PCBs in modern communication devices, their key characteristics, and the materials that make them indispensable in high-speed applications.

High-speed communication devices are essential components in modern technology, enabling the rapid transmission of data across various platforms and networks. These devices, including fiber-optic transceivers, 5G modules, high-frequency routers, and advanced wireless communication systems, facilitate seamless connectivity in industries such as telecommunications, aerospace, and data centers. By supporting faster data rates and lower latency, they enhance real-time communication, improve system efficiency, and drive innovation in applications like IoT, autonomous vehicles, and smart cities. As digital demands continue to grow, high-speed communication devices play a crucial role in shaping a more connected and responsive world.

The Growing Demand for High-Frequency PCBs

With the rapid expansion of 5G technology, IoT (Internet of Things), and autonomous vehicles, the demand for high-frequency PCBs has surged. According to a report by Grand View Research, the global high-frequency PCB market was valued at $4.5 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.2% from 2023 to 2030 (Grand View Research, 2023).

The growing demand for high-frequency PCBs (Printed Circuit Boards) is driven by the rapid advancement of modern communication technologies, including 5G networks, satellite systems, and high-speed data transmission devices. As industries increasingly adopt these technologies, there is a rising need for PCBs that can operate efficiently at higher frequencies while maintaining signal integrity, low loss, and high reliability. High-frequency PCBs are designed with specialized materials like PTFE, Rogers, or Teflon, which offer excellent dielectric properties and thermal stability. This surge in demand is also fueled by emerging applications in automotive radar, aerospace, and IoT devices, where performance and precision are critical. As a result, manufacturers are focusing on innovation and quality control to meet the stringent requirements of this growing market segment.

This growth is driven by the need for:

· Faster data transmission (5G networks require PCBs that support mmWave frequencies up to 100 GHz).

· Low signal loss to maintain data integrity.

· Thermal stability to prevent performance degradation in high-power applications.

Key Characteristics of High-Frequency PCBs

High-frequency PCBs (Printed Circuit Boards) are specifically designed to handle signals in the microwave and gigahertz frequency range, making them essential for advanced communication systems, radar, and high-speed digital applications. One of their key characteristics is the use of specialized materials like PTFE (Teflon), Rogers, or ceramic-filled laminates that offer low dielectric constant (Dk) and minimal dielectric loss, ensuring signal integrity at high frequencies. These PCBs also exhibit excellent thermal stability, tight impedance control, and low moisture absorption to maintain performance in demanding environments. Additionally, their design often includes precise manufacturing tolerances and advanced layout techniques to minimize signal loss, crosstalk, and electromagnetic interference (EMI).

1. Low Dielectric Constant (Dk) and Loss Tangent (Df)

High-frequency signals are sensitive to the dielectric properties of PCB materials. A low dielectric constant (Dk) ensures minimal signal delay, while a low dissipation factor (Df) reduces signal loss. Common high-frequency materials include:

· Rogers RO4000® series (Dk ~3.38, Df ~0.0027)

· PTFE (Teflon) (Dk ~2.1, Df ~0.0009)

· Isola IS680-350 (Dk ~3.6, Df ~0.0035)

2. Controlled Impedance and Signal Integrity

High-frequency PCBs require precise impedance control (typically 50Ω or 75Ω) to prevent signal reflections and crosstalk. Advanced manufacturing techniques, such as laser drilling and microvia technology, help maintain tight tolerances.

3. Thermal Management

High-speed circuits generate significant heat, which can degrade performance. High-frequency PCBs often use metal-core or ceramic-filled laminates to dissipate heat efficiently.

4. EMI/RFI Shielding

Electromagnetic interference (EMI) and radio frequency interference (RFI) can disrupt signal transmission. High-frequency PCBs incorporate ground planes, shielding layers, and specialized coatings to minimize interference.

Applications of High-Frequency PCBs

1. 5G and mmWave Technology

5G networks operate at sub-6 GHz and mmWave (24–100 GHz) frequencies, requiring PCBs with ultra-low loss materials to maintain signal strength over long distances (Microwave Journal, 2022).

2. Aerospace and Defense

Radar systems, satellite communications, and avionics rely on high-frequency PCBs for reliable signal transmission in harsh environments.

3. Automotive Radar and ADAS

Advanced driver-assistance systems (ADAS) use 77 GHz radar PCBs for collision avoidance and autonomous driving.

4. Medical Imaging and High-Speed Computing

MRI machines and high-performance computing (HPC) systems depend on high-frequency PCBs for fast, accurate data processing.

High-frequency PCBs are the backbone of modern high-speed communication systems, enabling faster data transfer, reduced signal loss, and improved reliability. As industries continue to push the limits of wireless technology, the demand for advanced high-frequency PCBs will only grow.

Investing in high-quality PCB materials and manufacturing processes ensures optimal performance in 5G, IoT, automotive, and aerospace applications, making high-frequency PCBs an essential component of next-generation electronics.

Choose DSX Electronics

for your high-frequency (HF) PCB needs and experience unmatched professionalism and quality. As a trusted industry leader, we specialize in designing and manufacturing HF PCBs that deliver exceptional signal integrity, low dielectric loss, and superior performance in high-speed applications. Our team of skilled engineers and technicians uses only the highest-grade materials, such as Rogers and PTFE, to ensure your boards meet the strictest standards for reliability and precision. Whether you're in telecommunications, aerospace, or advanced electronics, DSX Electronics offers tailored solutions, fast turnaround times, and dedicated customer support. Partner with us for your HF PCB projects — where expertise meets excellence.

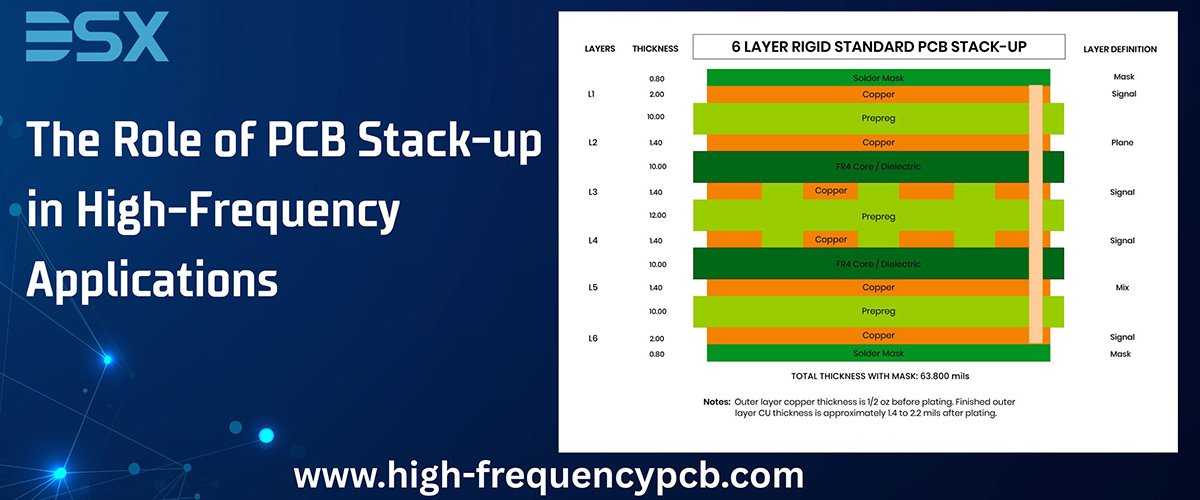

The Role of PCB Stack-up in Hi

The Role of PCB Stack-up in Hi

Why Are High-Frequency PCBs Es

Why Are High-Frequency PCBs Es

High-Frequency PCB vs. RF PCB:

High-Frequency PCB vs. RF PCB:

Why Signal Integrity Matters i

Why Signal Integrity Matters i