FR4 vs. Rogers: Which Material is Best for High-Frequency PCB Design?

When it comes to high-frequency PCB (Printed Circuit Board) design, the choice of substrate material plays a critical role in performance, reliability, and cost. Among the most commonly used materials in the industry are FR4 and Rogers laminates. While FR4 is a standard go-to for general PCB fabrication, Rogers materials are often preferred for RF and microwave applications. But which one is best for high-frequency PCB design?

Let’s dive into a detailed comparison of FR4 vs. Rogers materials to help you make the right decision for your next high-frequency project.

What is a High-Frequency PCB?

A High-Frequency PCB is a type of printed circuit board specifically designed to handle signals with high frequencies, typically starting from 500 MHz and above, and going up to several GHz (gigahertz). These boards are used in applications where fast signal transmission, low signal loss, and stable electrical performance are crucial.

Why Do We Need High-Frequency PCBs?

In modern electronics, especially in wireless communication, 5G, radar, satellite, and RF (radio frequency) systems, signals need to move quickly and accurately. Traditional PCB materials like standard FR4 can’t always handle these fast signals without introducing distortion, signal delay, or loss.

That’s where high-frequency PCBs come in. They are built using special materials (like Rogers, Teflon, or other low-loss laminates) that maintain signal integrity at high speeds.

Key Characteristics of High-Frequency PCBs

Feature | Description |

High-Speed Signal Support | Designed for signals in the GHz range |

Low Dielectric Loss | Reduces energy loss during signal transmission |

Stable Dielectric Constant (Dk) | Ensures consistent signal performance |

Low Dissipation Factor (Df) | Maintains signal strength and clarity |

Tight Impedance Control | Important for signal integrity, especially in RF circuits |

Understanding FR4

FR4 is a widely used PCB substrate material made from woven fiberglass cloth and epoxy resin that is flame resistant (hence the "FR" in its name). Known for its mechanical strength, durability, and cost-effectiveness, FR4 is the standard choice for most general-purpose printed circuit boards. It offers good electrical insulation and performs well in low to mid-frequency applications, typically up to 1 GHz. However, FR4 has limitations at higher frequencies, including a relatively high dielectric constant (around 4.3–4.8) and higher signal loss, which can affect signal integrity in high-speed or RF designs. Despite this, FR4 remains a popular choice due to its availability, affordability, and ease of fabrication.

FR4 is a glass-reinforced epoxy laminate material that is widely used in PCB manufacturing. It is popular for its low cost, mechanical strength, and good electrical insulation properties.

Advantages of FR4:

· Cost-effective and readily available.

· Good mechanical stability.

· Sufficient for low to mid-frequency applications (up to ~1 GHz).

· Easy to process and manufacture.

Limitations of FR4 in High-Frequency Design:

· High dielectric loss (Df) at high frequencies.

· Inconsistent dielectric constant (Dk), which can affect signal integrity.

· Higher signal attenuation over long traces.

Understanding Rogers Materials

Rogers materials are high-performance laminates specifically engineered for radio frequency (RF), microwave, and high-speed digital applications. Unlike standard FR4, Rogers substrates offer a low dielectric constant (Dk) and an exceptionally low dissipation factor (Df), which ensures minimal signal loss and consistent electrical performance even at frequencies exceeding 20 GHz. These materials also provide excellent thermal stability, tight impedance control, and reliable performance in harsh environments, making them ideal for 5G networks, aerospace, automotive radar, and advanced communication systems. Due to their specialized properties, Rogers laminates are widely trusted in industries where signal integrity and performance are mission-critical.

Rogers is a brand name associated with high-performance dielectric materials specifically designed for RF, microwave, and high-speed digital applications. These laminates offer superior electrical properties compared to FR4.

Advantages of Rogers:

· Low dielectric loss (ideal for GHz+ frequencies).

· Stable dielectric constant over a wide range of frequencies and temperatures.

· Better impedance control.

· Excellent for high-speed, high-frequency designs (5G, radar, satellite, etc.).

Disadvantages of Rogers:

· More expensive than FR4.

· May require specialized manufacturing processes.

· Longer lead times depending on supplier.

FR4 vs. Rogers: Key Property Comparison

Property | FR4 | Rogers (e.g., RO4350B, RO4003C) |

Dielectric Constant (Dk) | ~4.3 – 4.8 | ~3.38 – 3.66 |

Dissipation Factor (Df) | 0.020 – 0.030 | ~0.002 – 0.004 |

Frequency Range | Up to ~1 GHz | Up to 20+ GHz |

Cost | Low | High |

Thermal Stability | Moderate | Excellent |

Impedance Control | Less accurate | High precision |

When to Use FR4

You should use FR4 when your PCB design is for low to mid-frequency applications (typically below 1 GHz) where cost-effectiveness and mechanical strength are more critical than ultra-high signal performance. It's an excellent choice for general-purpose electronics, consumer devices, LED lighting, power supplies, and prototyping where signal loss and dielectric stability aren't major concerns. FR4 is also widely available, easy to manufacture, and supports multilayer designs, making it ideal for projects with tight budgets and less demanding electrical requirements. However, it’s not recommended for high-frequency RF or microwave circuits due to its higher dielectric loss and signal attenuation.

Choose FR4 if:

· Your application is low to mid-frequency (<1 GHz).

· Budget constraints are significant.

· The design doesn’t demand tight impedance control.

· You’re building prototype boards or consumer electronics.

When to Use Rogers

You should use Rogers materials when your PCB design involves high-frequency or RF applications, typically operating above 1 GHz, where signal integrity, low dielectric loss, and consistent electrical performance are critical. Rogers laminates offer a stable dielectric constant (Dk) and low dissipation factor (Df), making them ideal for sensitive designs like 5G communication systems, radar, satellite transmissions, aerospace electronics, and high-speed digital circuits. If your project requires precise impedance control, minimal signal distortion, and superior thermal stability, Rogers is the preferred choice—even if it comes at a higher cost compared to standard FR4.

Choose Rogers if:

· You're working on high-frequency or RF applications (>1 GHz).

· Your design needs precise impedance control.

· You require low signal loss and high signal integrity.

· Your product involves 5G, satellite communication, radar, or aerospace.

Which One is Best?

For high-frequency PCB design, Rogers is clearly the superior material due to its low dielectric loss, consistent electrical properties, and reliable performance in the GHz range. However, if you’re designing for lower frequencies or have strict cost limitations, FR4 is still a valid and efficient choice.

Ultimately, the choice depends on your application's requirements, performance goals, and budget. Many designers even use hybrid PCBs—combining FR4 and Rogers—to balance cost and performance.

Choose DSX Electronics

and let us help you select the perfect PCB material tailored to your project’s needs. Whether you're working on a cost-effective design using FR4 or a high-performance application requiring Rogers or other advanced laminates, our experienced team is here to guide you every step of the way. We understand the challenges of high-frequency PCB design and are committed to delivering solutions that balance performance, reliability, and budget. With DSX Electronics, you get more than just a supplier — you gain a trusted partner dedicated to helping your ideas come to life with precision and expertise.

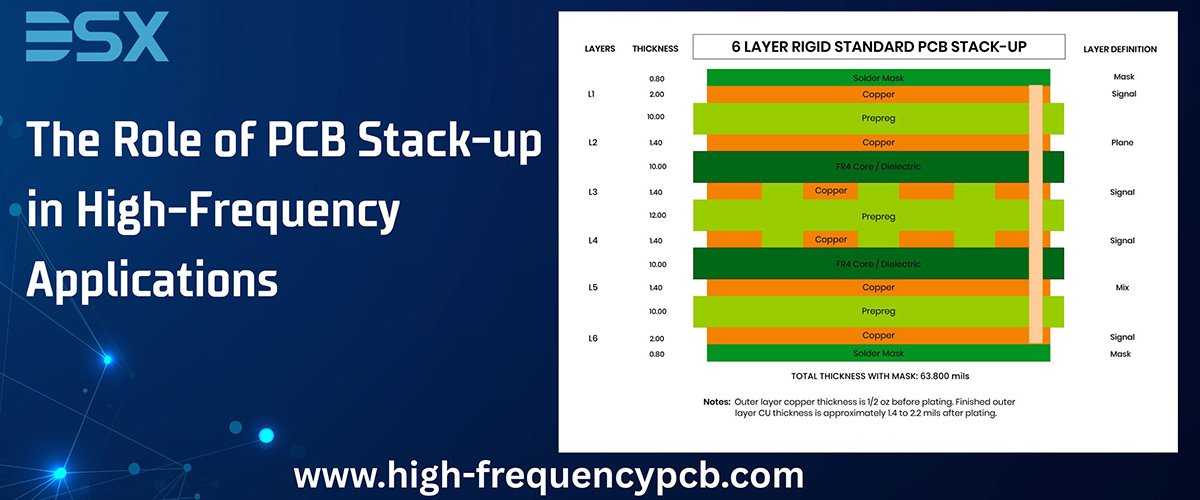

The Role of PCB Stack-up in Hi

The Role of PCB Stack-up in Hi

Why Are High-Frequency PCBs Es

Why Are High-Frequency PCBs Es

High-Frequency PCB vs. RF PCB:

High-Frequency PCB vs. RF PCB:

Why Signal Integrity Matters i

Why Signal Integrity Matters i