Key Materials Used in High-Frequency PCB Manufacturing

High-frequency printed circuit boards (PCBs) are essential components in advanced electronic systems, facilitating rapid signal transmission with minimal loss. The performance of these PCBs heavily depends on the materials used in their construction. At DSX Electronics, we specialize in manufacturing high-frequency PCBs, utilizing a range of materials tailored to meet specific application requirements. Below is an overview of key materials commonly employed in high-frequency PCB manufacturing, along with relevant research data. At DSX Electronics, we leverage our expertise to select and utilize these materials effectively, ensuring that our high-frequency PCBs meet the stringent demands of modern electronic applications.

Key Characteristics of High-Frequency PCBs:

High-frequency PCBs possess several key characteristics that make them suitable for applications involving rapid signal transmission and minimal signal loss. One of the most important features is a low and stable dielectric constant (Dk), which ensures consistent signal propagation speed and reduces distortion. These PCBs also have a low dissipation factor (Df), which minimizes energy loss during high-frequency operation, ensuring better signal integrity. Thermal stability is another critical attribute, as high-frequency circuits often generate more heat and must maintain performance across a wide temperature range. Additionally, controlled impedance is essential in high-frequency designs to prevent signal reflections and ensure accurate data transmission. Lastly, materials used in these PCBs typically exhibit low moisture absorption, which helps maintain electrical performance even in humid environments. Together, these characteristics enable high-frequency PCBs to function reliably in advanced technologies such as 5G, radar systems, and high-speed data communications.

· Low Dielectric Constant (Dk): A stable, low Dk ensures minimal signal distortion and improved transmission speed.

· Low Dissipation Factor (Df): Lower Df means less signal loss, especially at high frequencies.

· Thermal Stability: These PCBs must operate reliably under temperature variations without affecting performance.

· Controlled Impedance: Precise control of impedance is essential for signal quality at high frequencies.

- Low Moisture Absorption: Moisture can impact the electrical properties of a PCB; high-frequency boards must resist it.

Key Materials Used in High-Frequency

>>> Polytetrafluoroethylene (PTFE):

PTFE, widely recognized by the brand name Teflon, is renowned for its low dielectric constant (Dk) and low dissipation factor (Df), making it ideal for high-frequency applications. According to research, PTFE materials exhibit a dielectric constant ranging from 2.1 to 2.5 and a dissipation factor around 0.0004, contributing to efficient signal transmission with minimal loss. PTFE's excellent thermal stability and chemical resistance further enhance its suitability for demanding environments.

>>> Ceramic-Filled PTFE Composites:

Combining PTFE with ceramic fillers enhances mechanical stability and thermal conductivity while maintaining favorable electrical properties. Materials like Rogers RO4000 series and Nelco N4000-13 are examples of such composites. The Rogers RO4000 series offers a dielectric constant between 3.38 and 3.48 and a dissipation factor from 0.0021 to 0.0027, providing a balance between performance and manufacturability. Similarly, Nelco N4000-13 has a dielectric constant of 3.4 and a dissipation factor of 0.002, along with a high glass transition temperature (Tg) of 280°C, making it suitable for high-temperature applications.

>>> Liquid Crystal Polymer (LCP):

LCP is a thermoplastic material known for its low dielectric constant (approximately 2.9 to 3.2) and low loss tangent (0.002 to 0.003), making it suitable for high-frequency and millimeter-wave applications. Its excellent dimensional stability and low moisture absorption contribute to reliable performance in varying environmental conditions.

>>> Polyimide (PI):

Polyimide substrates are recognized for their high thermal stability, mechanical strength, and chemical resistance. With a dielectric constant typically ranging from 3.0 to 3.5, PI materials are used in flexible circuits and applications requiring durability at elevated temperatures.

>>> Hydrocarbon Ceramic Laminates:

These materials, such as those in the Rogers RO4000 series, combine hydrocarbon resins with ceramic fillers to achieve a balance of electrical and mechanical properties. They offer low dielectric constants and low loss tangents, making them suitable for high-frequency applications where cost-effectiveness and performance are critical.

>>> High-Density Interconnect (HDI) Laminates:

HDI laminates are advanced materials designed for high-layer-count and fine-line designs, suitable for high-speed data transmission and compact applications. They typically exhibit a dielectric constant between 3.0 and 4.0 and a loss tangent of 0.004 to 0.006, supporting operating frequencies up to 20 GHz.

>>> Ceramic Substrates:

Ceramic materials, such as alumina and barium titanate, offer exceptional electrical performance and high thermal stability. With dielectric constants ranging from 6 to 10 and loss tangents between 0.001 and 0.002, they are ideal for applications requiring high reliability and stability, supporting operating frequencies up to 60 GHz.

High-frequency PCBs are crucial in applications where fast signal transmission, low signal loss, and stable electrical performance are required. They are most commonly used in the following industries:

Use Case of High Frequency PCB

High-frequency PCBs are essential in advanced electronic systems where fast signal transmission and minimal signal loss are critical. One of the most prominent use cases is in 5G communication systems, where these PCBs enable high-speed data transfer between antennas, base stations, and devices, operating at frequencies as high as 24 GHz and beyond. In the automotive industry, high-frequency PCBs are used in radar systems for Advanced Driver Assistance Systems (ADAS), including blind spot detection, adaptive cruise control, and lane-keeping assistance. Similarly, aerospace and defense applications rely on these PCBs for aircraft radar, satellite communication, and secure RF systems. In medical technology, they play a vital role in devices like MRI machines and wireless patient monitoring, where signal accuracy and reliability are non-negotiable. Even in consumer electronics, such as high-speed Wi-Fi routers, GPS units, and Bluetooth devices, high-frequency PCBs ensure stable connectivity and fast data processing. These real-world use cases highlight the importance of precise materials and engineering—something DSX Electronics consistently delivers through expert design and manufacturing of high-frequency PCBs.

Telecommunications & Networking

· High-frequency PCBs are vital for:

· 5G base stations

· Radar systems

· Microwave communication

· Satellite communication

These systems often operate in the GHz range and need materials that support high-speed signals without distortion.

Automotive Industry

Used in:

· Advanced Driver Assistance Systems (ADAS)

· Radar and collision avoidance systems

· Vehicle-to-Everything (V2X) communication

These systems rely on millimeter-wave signals (e.g., 24 GHz or 77 GHz radar), which demand ultra-low-loss PCBs.

Medical Equipment

Especially in:

· MRI machines

· Ultrasound equipment

· Wireless medical monitoring devices

High-frequency PCBs ensure accurate data transmission and reliability in critical healthcare applications.

Wireless Devices & IoT

· Wi-Fi (2.4 GHz / 5 GHz)

· Bluetooth modules

· GPS devices

· RF identification systems (RFID)

As IoT continues growing, the need for compact, high-frequency PCBs rises rapidly.

Aerospace & Defense

Used in:

· Aircraft radar systems

· Electronic warfare

· Satellite systems

· Avionics

These environments demand not just high frequency, but high reliability and temperature resistance.

High-Speed Digital Devices

· Data servers

· Routers and switches

· High-speed processors

High-frequency PCBs help ensure signal integrity at very high data rates (10Gbps+).

Why Choose DSX Electronics for High-Frequency PCBs?

At DSX Electronics, we are highly specialized in designing and manufacturing high-frequency PCBs that meet the most demanding standards across industries:

· Precision manufacturing with tight tolerances

· Use of high-quality, certified materials (Rogers, Isola, Taconic, etc.)

· Advanced testing and inspection for signal integrity

· Custom RF board solutions for clients worldwide

· Rapid prototyping and mass production capability

Whether you're working on 5G infrastructure, aerospace radar, or cutting-edge IoT devices, DSX Electronics has the engineering expertise and manufacturing quality to deliver PCBs that perform reliably at high frequencies.

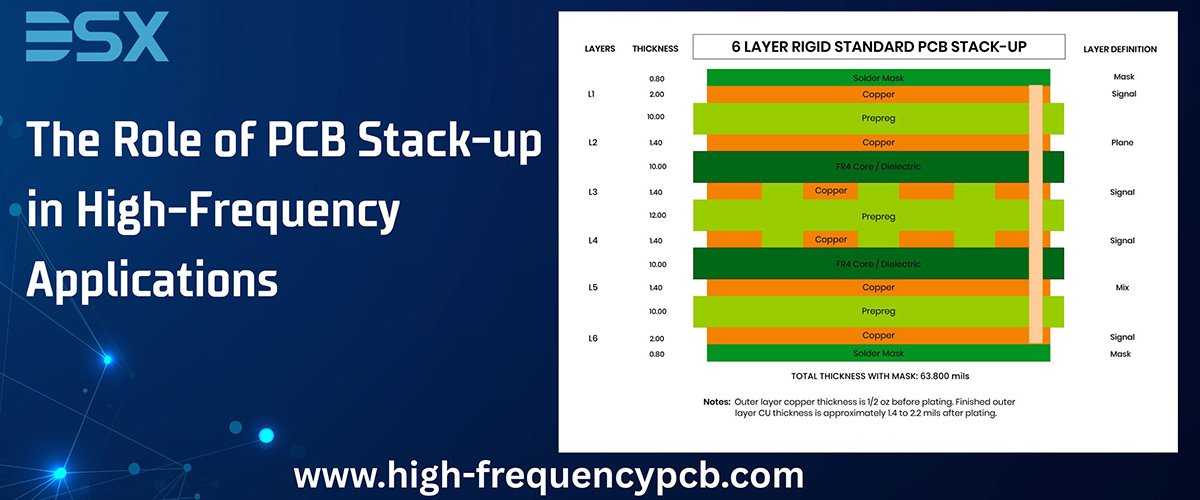

The Role of PCB Stack-up in Hi

The Role of PCB Stack-up in Hi

Why Are High-Frequency PCBs Es

Why Are High-Frequency PCBs Es

High-Frequency PCB vs. RF PCB:

High-Frequency PCB vs. RF PCB:

Why Signal Integrity Matters i

Why Signal Integrity Matters i