High-Frequency vs. Standard PCBs What’s the Difference

In the printed circuit boards (PCBs) industry, selecting the right type of board is critical for ensuring optimal performance. Two common types of PCBs are standard PCBs and high-frequency PCBs. While they may appear similar at a glance, their material composition, performance, and applications vary significantly. Understanding these differences can help in making the right choice for your specific needs. Here comes the DSX Electronics, we provide the best in quality services for your projects.

What is a Standard PCB?

Standard PCBs are widely used in consumer electronics, automotive, industrial equipment, and other general applications. These boards typically use FR4 (fiberglass-reinforced epoxy laminate) as the base material, providing adequate mechanical strength, electrical insulation, and durability for standard applications.

Key Characteristics of Standard PCBs:

Standard PCBs are designed for general-purpose electronic applications where cost-effectiveness and reliability are key. They are constructed using FR4, CEM-1, or CEM-3 materials, which offer good mechanical strength and electrical insulation. These boards operate efficiently at low to moderate frequencies, making them ideal for everyday electronic devices. While they provide moderate heat resistance, additional cooling mechanisms may be required for high-power applications. Standard PCBs are widely used in household electronics, automotive control systems, and basic communication devices, offering a balance of affordability and functionality.

>>> Material Composition: Generally made from FR4, CEM-1, or CEM-3 materials.

>>> Frequency Range: Operates efficiently at low to moderate frequencies.

>>> Cost-Effectiveness: More affordable to manufacture and suitable for mass production.

>>> Thermal Management: Moderate heat resistance, requiring additional cooling solutions for high-power applications.

>>> Applications: Commonly found in home appliances, automotive control systems, and basic communication devices.

What is a High-Frequency PCB?

A high-frequency PCB is specifically designed to operate at radio frequencies (RF) and beyond, typically above 1 GHz. These PCBs are engineered to minimize signal loss, reduce electromagnetic interference, and maintain signal integrity at high speeds. Unlike standard PCBs, which use FR4 as a substrate, high-frequency PCBs employ advanced materials such as PTFE (Teflon), Rogers, and ceramic-filled laminates, which provide low dielectric loss, high thermal stability, and excellent performance in high-speed applications. These boards are essential in industries that require precise and rapid signal transmission, such as telecommunications, aerospace, automotive radar, and medical imaging.

High-frequency PCBs are designed for applications requiring superior signal integrity and minimal signal loss at high frequencies. These boards utilize specialized materials such as PTFE (Teflon), Rogers, or other advanced composites that offer lower dielectric loss and improved thermal stability.

Key Characteristics of High-Frequency PCBs:

High-frequency PCBs stand out due to their exceptional performance in high-speed electronic applications. These PCBs are crafted using advanced materials like PTFE, Rogers, and ceramic-filled laminates, which ensure minimal signal loss and outstanding dielectric properties. Operating in the GHz range, they provide high signal integrity, reduced interference, and superior thermal stability, making them ideal for RF and microwave applications. Unlike standard PCBs, high-frequency PCBs can withstand extreme temperature fluctuations and maintain performance in demanding environments. Their low dielectric constant and loss tangent contribute to enhanced electrical efficiency, allowing them to be the preferred choice for high-speed data transmission and critical communication systems.

>>> Material Composition: Made from PTFE, Rogers, or high-performance ceramic-filled laminates.

>>> Frequency Range: Operates in the GHz range, making them ideal for high-speed signal transmission.

>>> Low Signal Loss: Enhanced signal integrity with reduced dielectric loss.

>>> Superior Thermal Stability: Designed to withstand extreme temperature variations.

>>> Applications: Used in RF communication, satellite systems, radar equipment, 5G technology, and military-grade electronics.

Applications of High-Frequency PCBs

High-frequency PCBs are widely used in industries where high-speed data transmission and low signal loss are critical. They are essential components in RF and microwave communication systems, including satellite and radar systems, where precision and reliability are paramount. The telecommunications industry relies on these PCBs for 5G infrastructure, wireless communication, and high-speed networking equipment. In the medical field, high-frequency PCBs are used in imaging devices such as MRI and CT scanners, ensuring accurate and real-time diagnostics. Aerospace and defense applications, including avionics and military radar, also depend on high-frequency PCBs for mission-critical operations. Their role in automotive radar systems for advanced driver-assistance systems (ADAS) further highlights their importance in modern technology.

High-frequency PCBs play a crucial role in modern technology, where fast and reliable signal transmission is essential. These boards are widely used in:

>>> Telecommunications: Essential for 5G infrastructure, satellite communications, and wireless networks.

>>> Aerospace & Defense: Used in radar systems, avionics, and military-grade electronic warfare systems.

>>> Medical Devices: Integral to imaging equipment like MRI and CT scanners, as well as advanced diagnostic tools.

>>> Automotive Industry: Found in advanced driver-assistance systems (ADAS), GPS, and vehicle-to-vehicle communication technologies.

>>> Industrial Applications: Utilized in automated control systems, IoT devices, and sensor-based networks.

Research Data on High-Frequency vs. Standard PCBs

Recent studies indicate that high-frequency PCBs outperform standard PCBs in terms of signal integrity, thermal stability, and longevity. According to a 2023 market report, the demand for high-frequency PCBs is expected to grow at a CAGR of 9.3% from 2023 to 2030, driven by the increasing adoption of 5G networks, IoT devices, and advanced radar systems. Research also shows that PTFE-based high-frequency PCBs experience up to 40% less signal loss compared to traditional FR4-based boards. Additionally, a study by IEEE found that high-frequency PCBs can improve data transmission efficiency by 35%, making them ideal for high-speed and precision-based applications in telecommunications and aerospace industries.

Differences Between High-Frequency and Standard PCBs

High-frequency PCBs and standard PCBs differ significantly in their material composition, performance, and suitability for various applications. Research indicates that high-frequency PCBs are engineered to handle signals with minimal loss and distortion at high frequencies (typically in the GHz range), whereas standard PCBs are typically used for lower frequency applications (below 1 GHz). A study by IEEE revealed that high-frequency PCBs experience up to 40% less signal loss compared to traditional FR4-based standard PCBs, which results in better signal integrity in critical systems like telecommunications and aerospace.

>>> Material Composition: High-frequency PCBs often use materials such as PTFE (Teflon), Rogers, and ceramic-based composites, which have low dielectric constants and loss tangents, allowing for faster signal transmission with reduced interference. On the other hand, standard PCBs are usually made from FR4, a fiberglass-reinforced epoxy laminate that is ideal for applications requiring moderate electrical and mechanical properties but insufficient for high-speed, high-frequency needs.

>>> Signal Integrity and Thermal Management: High-frequency PCBs are specifically designed to withstand extreme temperature variations and maintain performance under rigorous conditions, making them ideal for 5G networks, satellite communications, radar systems, and medical imaging devices. These PCBs are more stable at high frequencies, reducing signal degradation over long distances. In contrast, standard PCBs may suffer from increased signal loss and thermal instability when used in high-frequency applications, often requiring additional cooling solutions and compromising performance.

>>> Performance Metrics: According to a 2023 market study, high-frequency PCB demand is expected to grow at a CAGR of 9.3% from 2023 to 2030, largely driven by the increasing need for high-performance components in industries such as 5G infrastructure and automotive radar systems. In comparison, standard PCBs are more cost-effective for mass production, but they cannot meet the stringent performance criteria required for cutting-edge technologies like autonomous vehicles and real-time medical diagnostics.

>>> Applications Comparison: High-frequency PCBs dominate in industries where low signal loss, high data transmission speed, and thermal stability are critical, such as RF/microwave communication, medical imaging, and aerospace. Standard PCBs, while still essential in consumer electronics, home appliances, and automotive systems, are not suitable for high-speed applications that demand superior electrical efficiency.

Why Choose DSX Electronics for High-Frequency PCBs?

At DSX Electronics, we specialize in the design and manufacturing of high-frequency PCBs that meet the most demanding industry standards. Our expertise in material selection, precision engineering, and stringent quality control ensures that you receive PCBs with superior performance and reliability.

Why Partner with DSX Electronics?

>>> Expertise: Years of experience in high-frequency PCB manufacturing.

>>> Premium Materials: We use top-quality PTFE, Rogers, and other high-performance substrates.

>>> Advanced Technology: Cutting-edge manufacturing techniques ensure precision and efficiency.

>>> Customization: Tailored solutions to meet your specific RF and microwave PCB requirements.

>>> Global Reach: Trusted by international clients across telecommunications, aerospace, medical, and defense sectors.

When it comes to high-frequency PCBs, precision, material quality, and reliability are non-negotiable. Trust DSX Electronics for cutting-edge high-frequency PCB solutions that power the future of technology. Choose excellence—choose DSX Electronics!

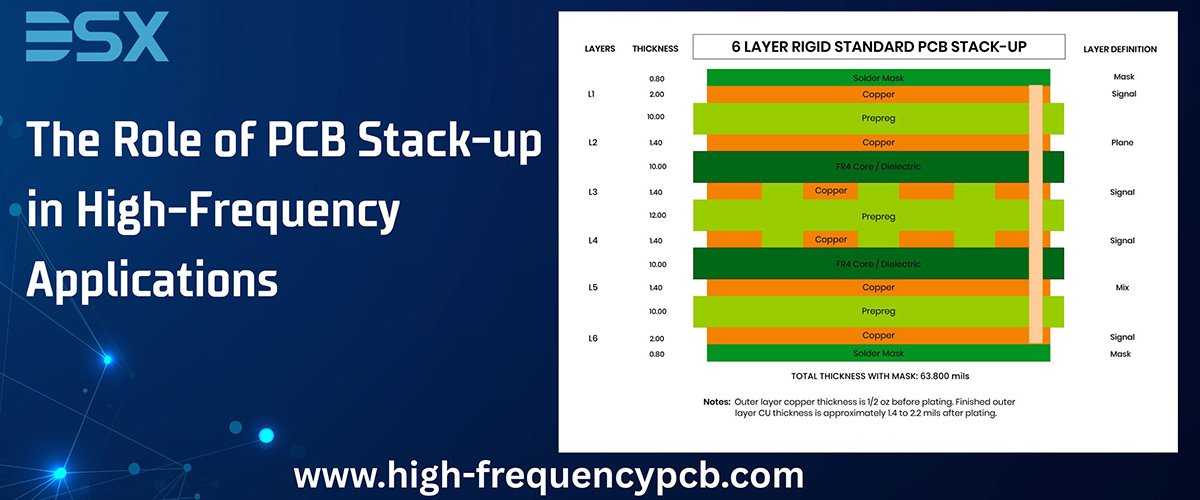

The Role of PCB Stack-up in Hi

The Role of PCB Stack-up in Hi

Why Are High-Frequency PCBs Es

Why Are High-Frequency PCBs Es

High-Frequency PCB vs. RF PCB:

High-Frequency PCB vs. RF PCB:

Why Signal Integrity Matters i

Why Signal Integrity Matters i